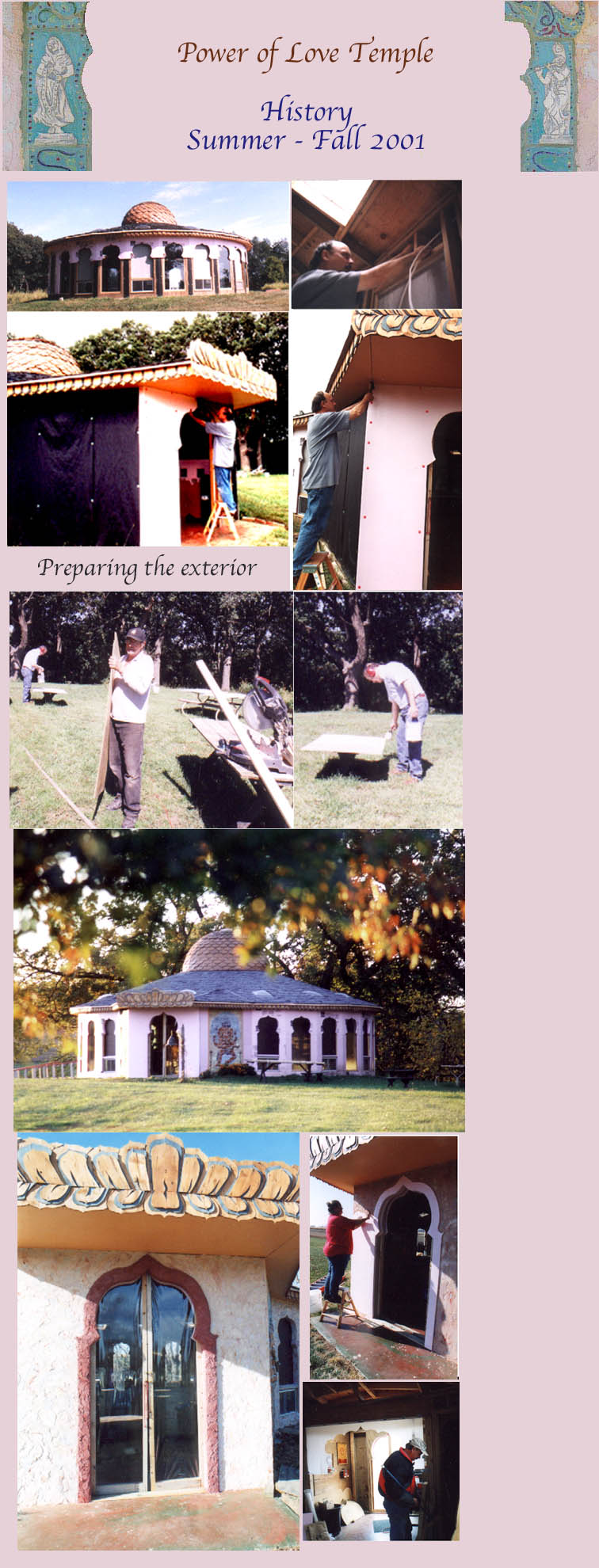

At last the roof was done and time to move on. Leela had cut and stained the 3 layers of lotus shaped shingles and installed them on the fascia when no one was around.

Steve Kelley and Dale worked at pushing and pulling the electrical wires through the walls.

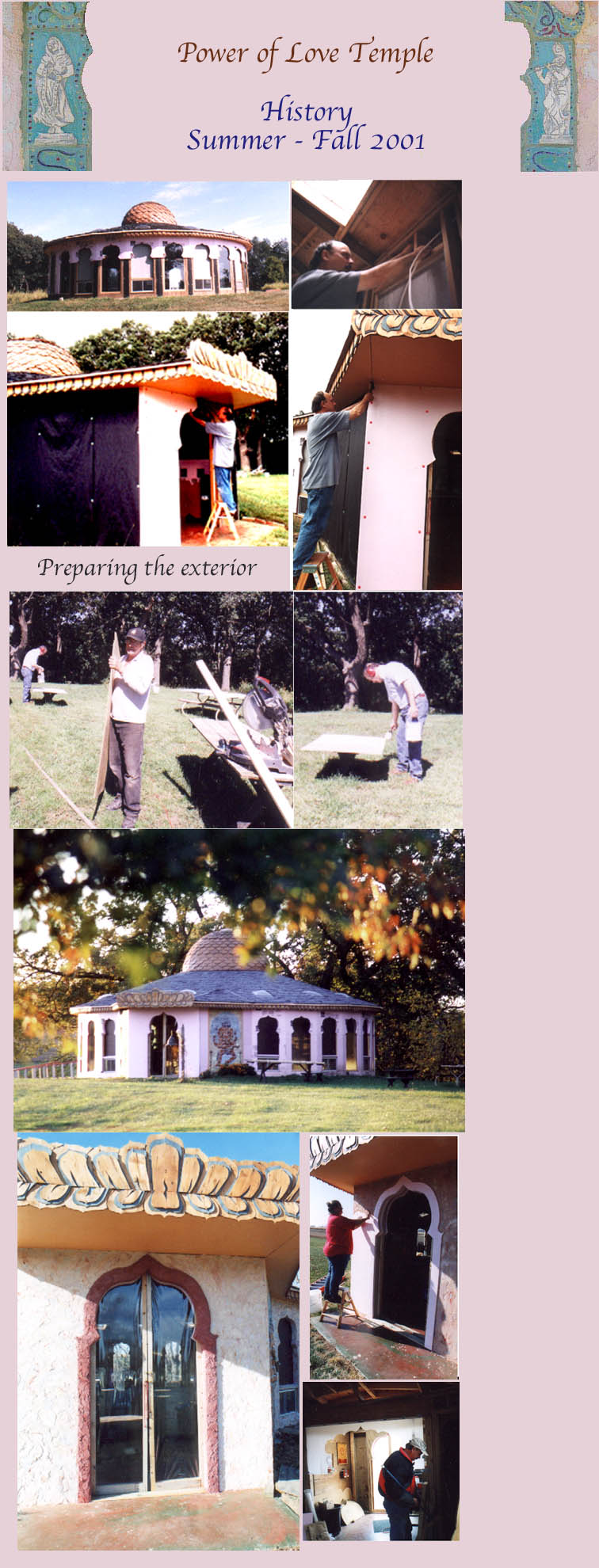

There is a cement product called foam guard that is a stucco that will adhere to styrofoam. This saved immense hours with not having to put metal lathe around all the windows and sculpture wells.

Steve is helping to install it around the door.

Dale and Steve helped to cut, paint and install the pieces of concrete board that would go into the sculpture wells.

By the time the trees turned color, the whole exterior had extruded polystyrene over it. This also gave us added insulation.

Leela mixed different colored cement dye into making the stucco and hand troweled it onto the temple. This was a very lengthy process. Polystyrene does not have a UV filter so where it was in the direct sunlight over a long time, it turned to dust. It had to be applied while the temperature was above 50 degrees for 24 hours. With winter fast approaching construction needed to take a different bend.

We purchased a sound system for the temple and again Steve Kelley came to install it. Good acoustics were a priority for musicians.